We made tremendous progress this week. We completed the shaping we needed to do prior to gluing the front and back halves together and then assembled the body. My recent travel schedule has indeed slowed progress, but on the weekends we try and take a break from homework and lab work to draw designs, carve wood, and imagine the finished bass.

We marked the size of the three potentiometers that control the volume, bridge pickup, and neck pickup, and then cut the minimum cavity needed to access them once we assemble everything. We also sketched out and then routed 3 grooves in the walnut back. The channels would become holes for the wires once everything was glued together.

To complete the control panel, we designed a template for a pleasantly shaped panel cover that would eventually hide the electronics. Cut about a 1/4 inch down, the shelf would allow us to put some attractive zebrawood over the electronics, secured with a few machine screws. We will make the zebrawood cover and drill holes for the screws last — we need to focus on a working instrument first.

With the exotic hardwood front and the walnut back nearly ready, we examined how the pieces fit together. The 1/4″ phono jack needed special cutting; centering the plug socket into the edge would require a 1/2 round groove in each half that could precisely mate to the diameter of the threaded socket.

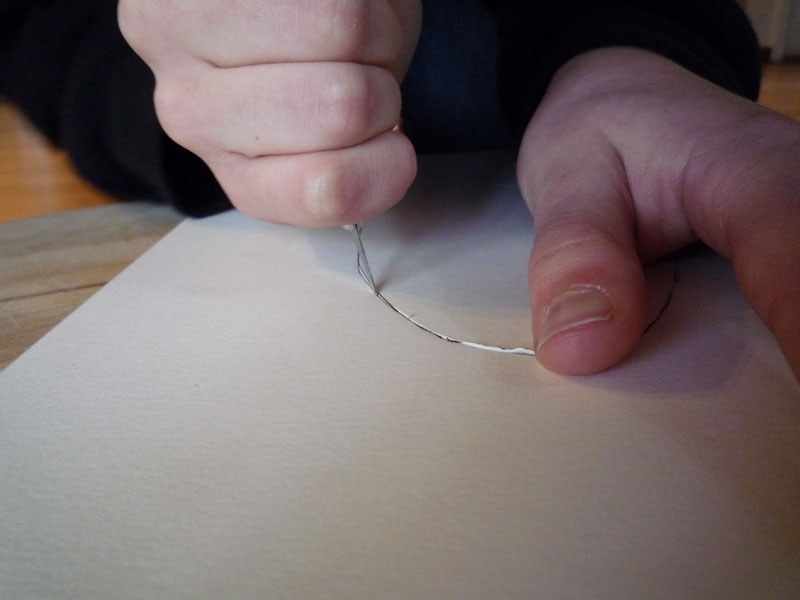

Everything now rested on our strategy for gluing. We had put weeks of work into designing, precision cutting, planing, sanding, and aligning. Gluing the front and back faces was irreversible. A poor setup or misalignment would be impossible to correct. We spend hours doing final smoothing and planning for the final joint. Tinting some wood glue let us experiment with colors that would blend nicely with walnut.

Previous experience has taught us that there is no such thing as too many clamps.

And of course, every luthier knows the kitchen table is the ideal location for gluing. In the dim light of morning, Emily nearly shrieked after discovering an alien-looking medical probe, lying in wait on the kitchen table.

After removing the clamps, we could finally appreciate the body’s study feel and smooth curvaceous body. Rather than do the last routing for the neck pocket, we impatiently started final shaping. The 1/2″ radius rounding bit on the router threw purpleheart and cocobolo shavings off the corners. Paul and I could not stop tracing the outline of the rounded edges with our hands.

It was time to apply 80 grit sandpaper. Our final significant challenge is making the jig and then routing the neck. Once again, we feel the stress. If the pocket is too deep, the “action” will be wrong, and the bass will be unplayable. If the pocket is crooked, the sound could suffer. This weekend will be the final test.

I can’t wait to see it !!! Wow, what a fantastic project. You guys are fantastic and Opa and I can’t wait to pat you on your back!