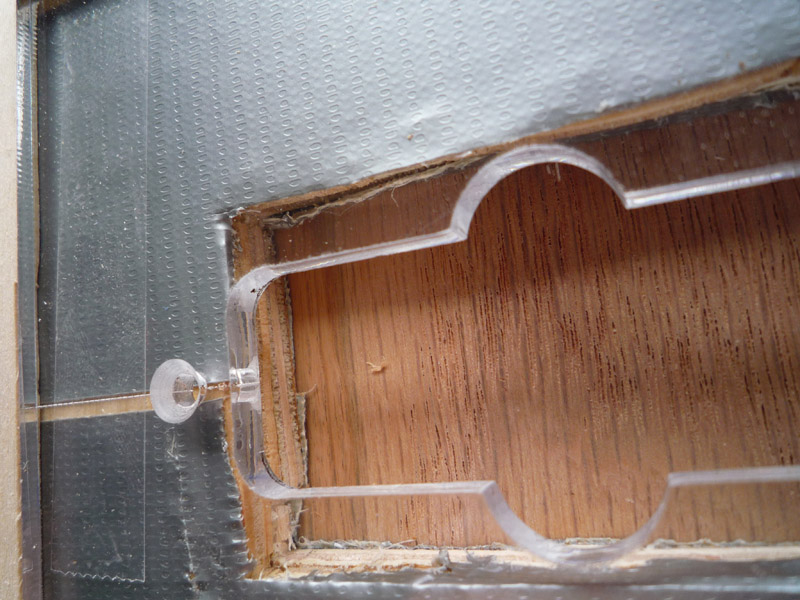

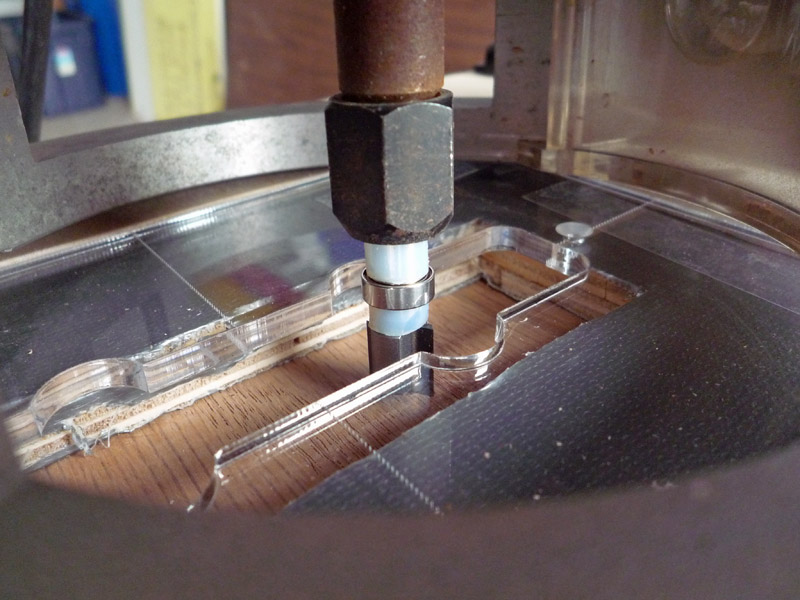

We got a tremendous amount of work done today on the bass. It seems that all of woodworking can be reduced to making jigs or sanding. We started by building several frames to hold the routing template for the pickup. The routing bit came with a small sleeve ball bearing that is exactly the same diameter as the router bit. We cut a bit of teflon tubing to put above and below the sleeve, to keep it precisely in place, against the template.

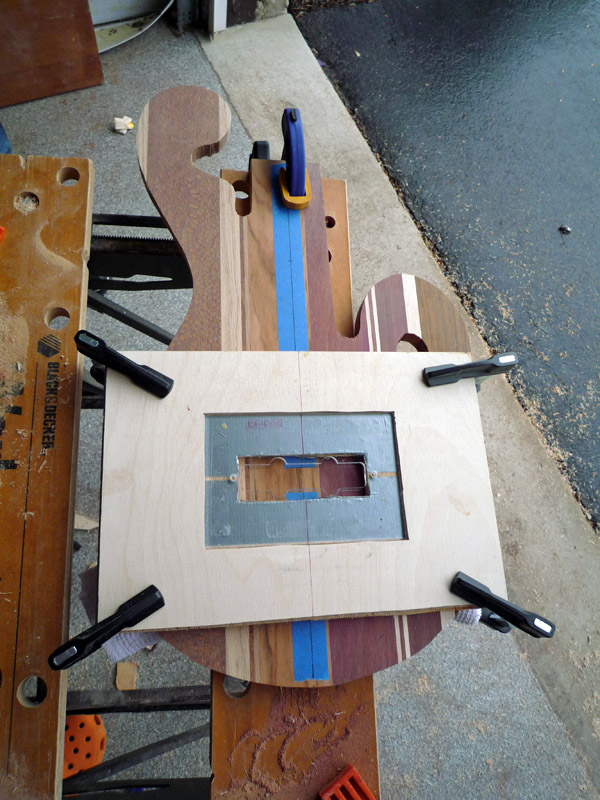

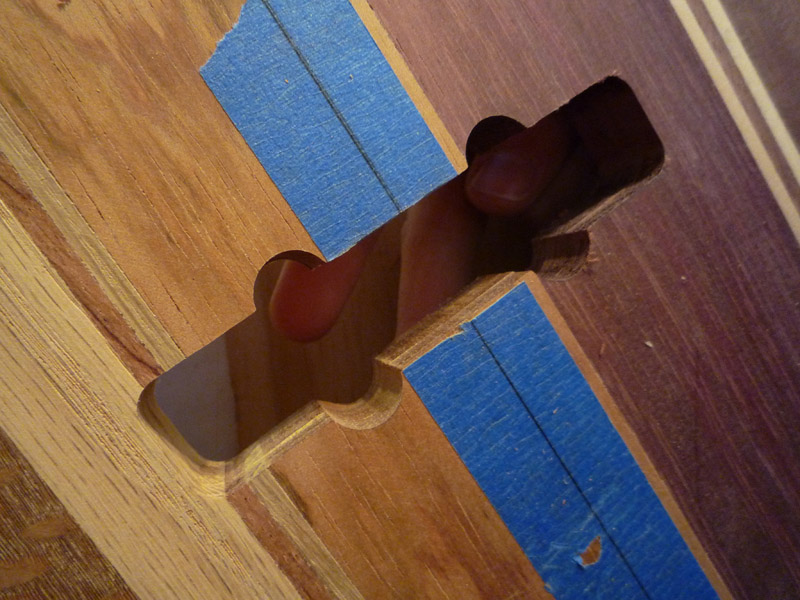

We had one fantastic stroke of luck while testing our setup on the walnut. After routing the hole, we grabbed one of the pickups to test the fit…. it would not. We scratched our heads and then tried the other pickup. It fit! Suddenly, we realized the two pickups were not identical, and the template we had fit one, but not the other.

Yikes! Had we not accidentally grabbed the wrong pickup, we would have used the template to route both pickup holes, and then would have had to do some ugly stretching of the hole to fit the pickup. So after routing the intended hole we spent about an hour carving a template of our own for the other pickup. Whew, close call.

We were a bit worried about the purpleheart. When we were using the plane to level the surface the purpleheart suffered “tearouts” easily. We were also nervous about routing the thin laminated strips, but with the new sharp blade and making 3 passes to work our way through the 3/4th” made the work easy.

While I when to pickup a celebratory pizza, Paul took the neck and bridge off his old base and decided where he wanted to put the control knobs. We then mock assembled the pieces to see how they would look. We will need to pick up some long-neck potentiometers, since they have to make it through 3/4″.

Then it was time to relax… We had pizza, and I kicked back with a beer. Then we topped the evening off by watching Netflix.