Well, although we have made tremendous progress, we are currently in the doldrums of small tasks that seem to last longer than they should, and when completed, appear too insignificant to be considered accomplishments.

Nevertheless, we press on.

The tuning is nearly complete. 55 ruddy bars lay beautifully, but still silently on a table in the front room. They are splendidly tuned. I sat in the red box, grinding bits of wood and striking the bar while Paul managed 2 computers and analyzed the sounds. A spreadsheet of our design calculated each frequency, and a formula we constructed helped us “stretch” the highest notes.

Human hearing is imperfect in the highest and lowest ranges. High notes are heard by our brains as flat. It is intriguing. We have to make them sharp (based on the measured frequency) to hear them in tune. In the low ranges notes must be flattened.

We have 6 bars that we have to re-make. We have cut them, and now need to drill the string holes and shape them. Most of them are in a range where the fundamental and the first harmonic are NOT a perfect two octaves apart. The first time we tried to tune that range our strategy failed. This time, we will shoot for an octave and a sixth as the harmonic.

The video below shows a properly tuned bar. Three tones are heard: the second harmonic, the first harmonic, and the fundamental. The fundamental is so low, the little video camera has trouble picking it up.

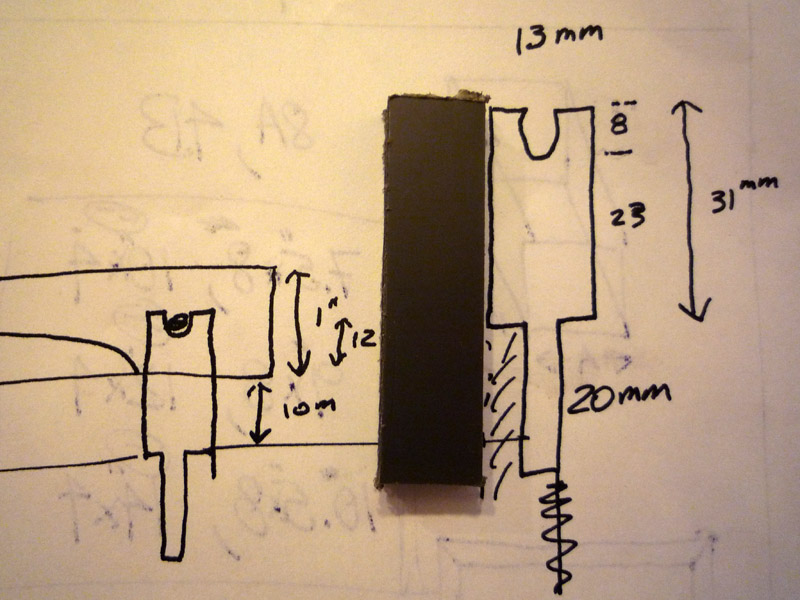

Our next big milestone will be mounting the bars on some rails so Paul can play them. To do that, we must design and build 3 pieces: the rails, the rail hinges, and the posts. We will describe the rails in subsequent blog posts. Initial post construction is described below.

Marimba bars are suspended by a cord so they can vibrate freely when struck. Between each bar a small post suspends the cord. On commercial marimbas the post is a small machine-stamped piece of aluminum. They often get bent. We have been exploring materials that might make better posts, and be relatively easy for us to fashion. A very strong nylon could do the trick. One interesting type of nylon that is sold by the commercial name Nylatron contains Molybdenum Disulfide. MoS2 is a grayish metal that is slippery. In many ways it is like graphite. When the particles are vanishingly small, it is a dry lubricant. Put into nylon, it makes a bit more slippery. Of course, we are exploring new territory with this material. It may not work. However, this entire project is an exploration, why stop now?

A laser cutter would have been the perfect way to cut the Nylatron. But instead of vaporizing bits of the 1 foot x 1 foot sheet with blasts from an invisible laser, we choose to try our hand at sawing and cutting.

The nylon was tougher than expected, and a bit of lubricant on the hack saw blade spend our progress

Polyrhythms

Paul must play music. While we work on the marimba, Paul has been working on snare drum set skills. He watches Drum Corp International shows on YouTube, plays the video in 1/2 time, transcribes what he hears into music, and then practices the new rhythms.

He has been particularly interested in polyrhythms. One of Paul’s drum instructors encouraged Paul to put together a class. So last Thursday (June 28th), Paul taught a class.